This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Rolex World Service: ticking for eternity

By Rory FH Smith | 10 March 2022 | Lifestyle

Discover the inner workings of the network – ensuring watchmaker Hans Wilsdorf ’s creations will forever stand the test of time

When Hans Wilsdorf established his watchmaking business in London in 1905, he did so with the intention that his creations would live on – and on, and on. Wilsdorf was born in Bavaria, Germany, in 1881, into an age when watches were fragile and wristwatches were largely considered to be women's jewellery items, far from robust enough to withstand the rigours of everyday life. Aged just 24, Wilsdorf wanted to make a new kind of watch, which would live up to the active lifestyles of people in the 20th century.

Wilsdorf and his newly minted Rolex brand created the Oyster – the world’s first waterproof wristwatch. The compact piece went on to prove its durability in 1927, when Mercedes Gleitze became the first British woman to swim the English Channel – with a Rolex Oyster strapped securely to her wrist. At that moment, she became the first testimonee for the brand – a title that would be bestowed to only select few great sportspeople, adventurers and artists who embodied Wilsdorf's founding principles of, as Rolex calls it, “perpetual excellence”.

While making innovative, robust wristwatches was a considerable achievement, there was another pressing question developing as the popularity of his timepieces grew: how to maintain the excellence of each watch as time passed. Intent that each of his watches should be an “ambassador for quality”, as more of Wilsdorf ’s creations found their way around the world, he needed a global solution for servicing and maintenance.

Today, the Rolex World Service is a global network of watchmaking workshops tasked with ensuring each timepiece receives the same level of service wherever they are in the world. Situated on every continent (except for Antarctica), one of its most impressive centres is they eight-storey facility in the Harwood District of Dallas, designed by the Japanese architect Kengo Kuma and finished in 2018.

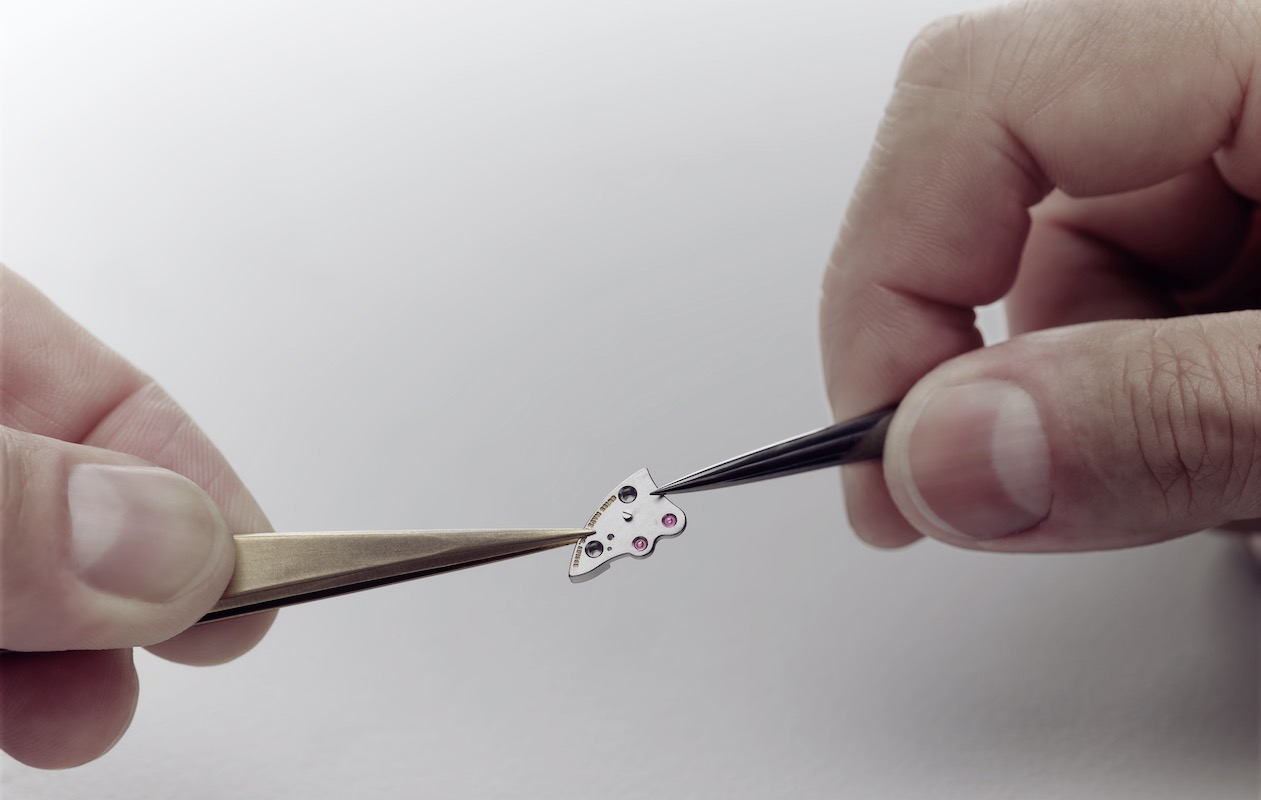

Each centre is run by specialist watchmakers, who have earned their stripes through Rolex’s 18-month training programme, which enables them to carry out full servicing on Oyster movements. While the inner workings of the service centres are largely hidden behind closed workshop doors, the Rolex World Service offers a meticulous 13-step process that covers everything from initial assessment and evaluation of the watch’s components, all the way through to polish, finishing and handover.

Every service starts with an initial assessment before the work can start in earnest. A few exceptional historic pieces, whose refurbishment requires specific skills, are handled by Rolex’s specialist restoration atelier at the company’s headquarters in Geneva.

Next, the watch is prepped for service, removing the movement – still fitted with its dial and hands – from the case, which has already been detached from the bracelet. Once separated, the movement, case and bracelet all follow separate paths during servicing before being reassembled at the end of the process.

The watchmaker dismantles the movement to inspect each component, replacing those that no longer meet the requirement. With the watch carefully broken up, its many components are cleaned using an ultrasonic bath to remove all trace of impurities. Once cleaned and dried, the movement is reassembled and lubricated. Only then does the watchmaker start to make adjustments to the precision of the movement.

Like the movement, the case is completely disassembled and the middle case, bezel, case back and bracelet are re-polished or satin- finished according to how they were originally produced. Using high-speed polishing tools and

steady hands, the metalwork is brought as close to the original finish as possible – or left with its charismatic nicks and scratches on show, depending on the owner’s preference.

Once finished and the watchmaker is satisfied with the results, the case parts are reassembled and the seals replaced. At this point, the case is tested for waterproofness, just as Wilsdorf intended when he first created the Oyster back in 1926.

As the watch gradually starts to come back together, the movement – to which the dial and hands have been refitted – is put back into the case after it’s been mechanically and visually checked. Once all the components are united with each other, it’s time for testing to begin. The watchmaker measures its chronometric precision and makes any final adjustments. The case back is then screwed down and the watch undergoes a rigorous test lasting a minimum of 24 hours, to verify the performance of the movement over time.

Finally, he watch is submerged in water and pressure tested to ensure it’s fully watertight and lives up to its depth rating. Only then is the bracelet re-joined before it, too, undergoes a final inspection ahead of collection, and the issuing of a two-year guarantee on parts and labour.

Just like a house or a car, a fine watch requires care, attention and occasional maintenance to ensure it stands the test of time. As a stickler for detail and unwavering in his quest to develop the world’s greatest watches, Wilsdorf ’s perpetual desire to see the brand become the best in the world lives on, long after his death in 1960.

With strong desirability and the iconic five- pointed crown still shining bright over a century on, it’s unsurprising that Wilsdorf ’s global network of service centres remains dedicated to keeping every Rolex ticking for eternity.